Whether food, pharmaceutical and cosmetic products or packaging machines: We are there to assist you with everything as your partner for packaging solutions. Guided by flexibility.

First and foremost is our experience. With our knowledge and Neugart technology, we are present everywhere packaging and labeling takes place. We succeed with our modular product portfolio. Because our gearboxes for the packaging industry are dynamic, robust and they guarantee smooth production.

Neugart in the Rolls-Royce of packaging machinery

With 150 employees at its headquarters in Flanheim, ECONO-PAK specializes in packaging machines for the food industry, especially frozen food, and the non-food industry. The company has well over 1000 systems in operation worldwide. In the field of top-load machines, ECONO-PAK is actually the global market leader. Moreover, we were able to master a very special challenge for ECONO-PAK.

Not just a packaging machine, a packaging center

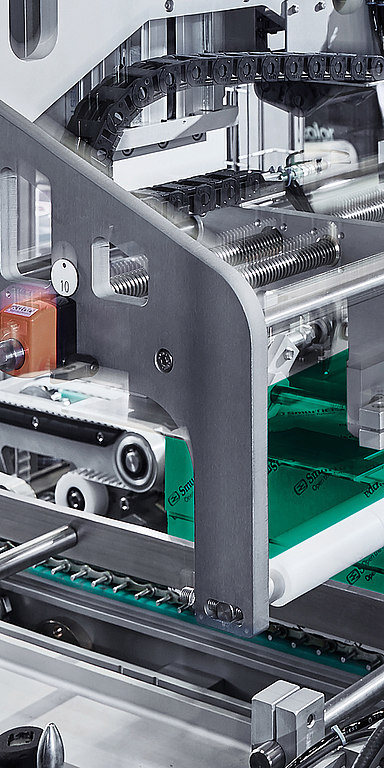

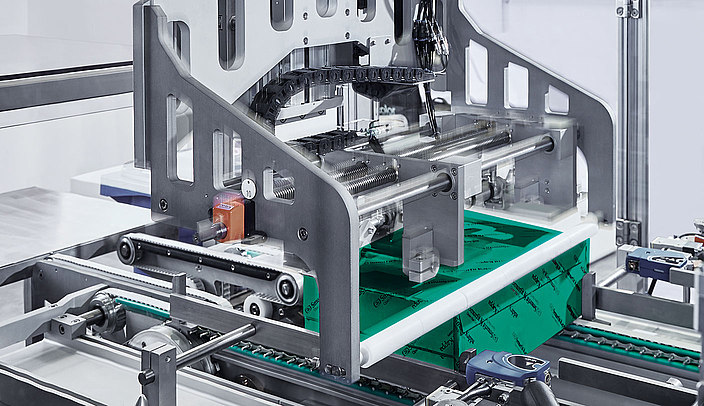

The SP-I-24 case packer is a highly complex, fully automated packaging center. In this system, cut-to-size cartons are processed as outer carton trays or wrap-around cartons. The stacking unit picks up products and positions them inside the outer packaging. This outer packaging is then folded in several process steps, wet with glue and finally sealed in the closing unit as a finished package.

All of this works with a servo motor and planetary gearbox. The challenge here: Different products always require adapted packaging. To meet this challenge, the SP-I-24 is designed to be very flexible. The gearbox must also be able to accommodate this flexibility. Even more so in terms of the required operational reliability. This is exactly where our work was needed.

Contamination-proof - since food-grade lubricants are used

An extra that we provide with our gearboxes and used in ECONO-PAK systems:

Food-grade lubrication. Thus, even in the event of a crash or failure, the product being packaged will never be contaminated.

Customization - not an issue for us

We can meet most customer requirements quickly and easily using our modular system. At ECONO-PAK, however, around 30% of all gearboxes used deviate from the commonly encountered market standard. So we customize them. We do this quickly, cost-effectively, safely and reliably.

Strong technical contribution as a supplier

To receive technical approval for use of our gearboxes in the SP-I-24, we had to pass many tests. First of all, in ECONO-PAK's in-house packaging machines. Then in the second step, our Neugart gearboxes were successfully installed and tested in field test machines.

However, the fact that our gearboxes technically meet all the requirements was only part of the process. The decisive factor was also our coherent package of experience and advice.

Experienced ECONO-PAK technicians find our gearboxes "simply good" today. Furthermore, they confirm: "In all these years, we have never had to replace a Neugart gearbox in the field".

The decisive factor: our total package

When it comes to the performance we bring to the packaging industry with our gearboxes, it's the breadth of our expertise that counts:

- Our planetary gearboxes can be designed in a wide range of variants by using a modular principle. The result: an economical purchase price with top quality.

- An additional bonus is our intelligent software, which allows you to quickly and intuitively find the right gearbox for your own application. Here we make complexity simple and we bring many factors to the best common denominator.

- Add to this our experience and the robustness of our gearboxes. After all, our customers need reliable technology. We deliver it to them with our cleverly designed planetary gearboxes.

A look into the future

Hygienic aspects increasingly important

From ECONO-PAK's point of view, the issue of hygiene is becoming more crucial in the packaging industry. Likewise, the ease of cleaning all components. Edges or points where deposits can accumulate must be eliminated and components have to be protected with paints or manufactured in stainless steel. In this regard, we monitor the trends together with ECONO-PAK in order to address the changes in the market.

"The operational reliability of our machines is our top priority. Neugart has always provided a coherent consulting package for all projects. What was promised to us by Neugart in the discussions could always be confirmed in the real-world applications. That's exactly how we envision a partner."

Markus Zerbe | Head of Sales | ECONO-PAK

Downloads

Would you like to start a project together?

We would be happy to help you!

Neugart Sales Team

Let's stay in touch

Subscribe to our newsletter

Be the first to know about new products, trade shows, training dates and stay up to date.

Subscribe