- Home

- Knowledge & News

- News

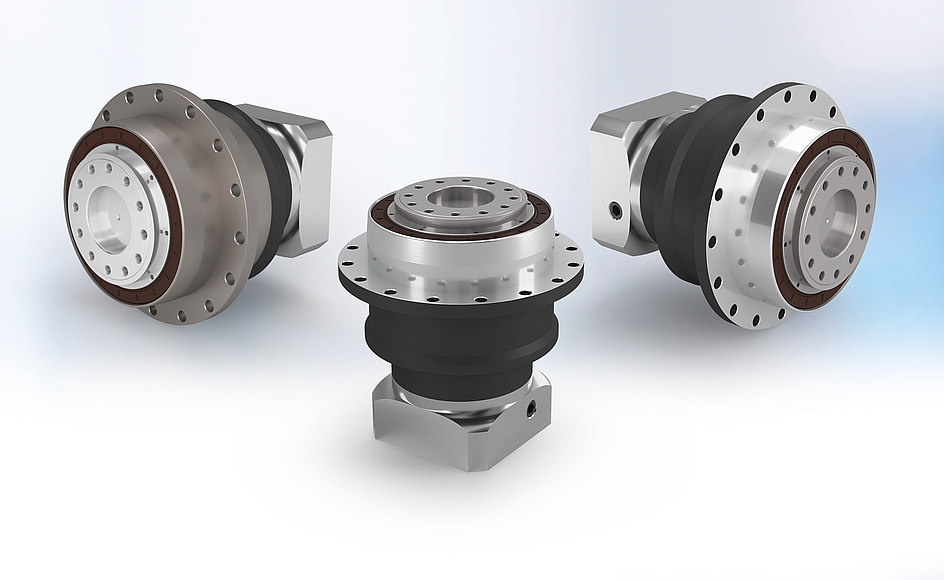

Application-specific NDF gearbox for Delta robot drives

As a follow-up to the NGV, the planetary gearbox for industrial automated guided vehicle, and the hygienic HLAE, Neugart now has, with the new NDF, an additional gearbox solution for a specific area of application in its portfolio: the newly developed product has been designed specifically for use in Delta robot arm drives.

As parallel-arm robots with tripod kinematics, Delta robots combine very fast movements with high positioning accuracy. This results in specific requirements for the servo motors of the main drives - and for the corresponding gearboxes. As a result, these gearboxes must meet the highest demands, especially in terms of stiffness and torsional backlash, in order to ensure the necessary precision even at full speed.

The Neugart NDF gearbox meets these special requirements with numerous technical details: For example, the gearbox enables extremely fast changes of direction thanks to a low-inertia clamping system at the input stage, which improves the dynamics and thus the cycle time of the robot. At the same time, the torsional backlash is limited to < 1 arcmin as a standard feature.

The output of the NDF has also received special attention in order to optimally meet the specific requirements of a Delta robot: The gear ratio at the output is i=5.5, which allows transmission of very high torques. A special radial shaft sealing ring ensures optimum sealing of the shaft during rapid changes of direction. A food-grade oil lubrication system, a stainless steel output shaft and a nickel-plated output flange are available as options for the NDF.

Let's stay in touch

Subscribe to our newsletter

Be the first to know about new products, trade shows, training dates and stay up to date.

Subscribe